Katrangan Produk

Informasi Standar - ASME/ANSI B16.5 & B16.47 - Flensa Pipa lan Fitting Flensa

Standar ASME B16.5 nyakup macem-macem aspek flensa pipa lan fitting flensa, kalebu rating tekanan-suhu, bahan, dimensi, toleransi, penandaan, pengujian, lan penetapan bukaan kanggo komponen kasebut. Standar iki kalebu flensa kanthi sebutan kelas rating wiwit saka 150 nganti 2500, sing nyakup ukuran saka NPS 1/2 nganti NPS 24. Standar iki nyedhiyakake syarat ing unit metrik lan AS. Penting kanggo dicathet yen standar iki diwatesi mung kanggo flensa lan fitting flensa sing digawe saka bahan cor utawa tempa, kalebu flensa wuta lan flensa reduksi tartamtu sing digawe saka bahan cor, tempa, utawa pelat.

Kanggo flensa pipa lan fitting flensa sing luwih gedhe tinimbang 24" NPS, ASME/ANSI B16.47 kudu dirujuk.

Jinis Flange Umum

● Flensa Slip-On: Flensa iki umume dipasang ing ANSI Kelas 150, 300, 600, 1500 & 2500 nganti 24" NPS. Flensa iki "dilebokake" ing ndhuwur pipa utawa ujung fitting lan dilas ing posisine, saengga bisa dilas fillet ing njero lan njaba flensa. Versi reduksi digunakake kanggo nyuda ukuran garis nalika papan winates.

● Flensa Leher Las: Flensa iki nduweni hub lancip dawa sing jelas lan transisi kekandelan sing lancar, njamin sambungan las penetrasi lengkap menyang pipa utawa fitting. Flensa iki digunakake ing kahanan layanan sing angel.

● Flensa Sambungan Pangkuan: Dipasangake karo ujung stub, flensa sambungan pangkuan diselipake ing sadhuwure fitting ujung stub lan disambungake kanthi ngelas utawa cara liyane. Desain sing longgar ngidini penyelarasan sing gampang nalika perakitan lan pembongkaran.

● Flensa Pendukung: Flensa iki ora nduweni permukaan sing munggah lan digunakake karo cincin pendukung, nyedhiyakake solusi sing efektif biaya kanggo sambungan flensa.

● Flensa Berulir (Sekrup): Dibor supaya cocog karo diameter njero pipa tartamtu, flensa berulir dikerjakake nganggo ulir pipa sing meruncing ing sisih mburi, utamane kanggo pipa bor sing luwih cilik.

● Flensa Las Soket: Mèmper karo flensa slip-on, flensa las soket diolah supaya cocog karo ukuran soket pipa, saéngga pengelasan fillet ing sisih mburi bisa ngamanake sambungan. Biasane digunakake kanggo pipa bor sing luwih cilik.

● Flensa Buta: Flensa iki ora duwe bolongan tengah lan digunakake kanggo nutup utawa mblokir pucuk sistem perpipaan.

Iki sawetara jinis flensa pipa sing umum digunakake ing macem-macem aplikasi industri lan komersial. Pilihan jinis flensa gumantung saka faktor-faktor kaya tekanan, suhu, lan jinis cairan sing diangkut, uga syarat proyek tartamtu. Pemilihan lan pemasangan flensa sing tepat penting banget kanggo operasi sistem perpipaan sing aman lan efisien.

Spesifikasi

| ASME B16.5: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| EN 1092-1: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| DIN 2501: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| GOST 33259: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| SABS 1123: Baja Karbon, Baja Tahan Karat, Baja Paduan |

Bahan Flens

Flensa dilas menyang pipa lan nozzle peralatan. Mula, digawe saka bahan-bahan ing ngisor iki;

● Baja karbon

● Baja paduan rendah

● Baja tahan karat

● Kombinasi bahan Eksotis (Stub) lan bahan pendukung liyane

Dhaptar bahan sing digunakake ing manufaktur wis dijamin ing ASME B16.5 & B16.47.

● ASME B16.5 - Flensa Pipa lan Fitting Flensa NPS ½” nganti 24”

● ASME B16.47 - Flensa Baja Diameter Gedhe NPS 26” nganti 60”

Gradasi bahan tempa sing umum digunakake yaiku

● Baja Karbon: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Baja Paduan: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Baja Tahan Karat: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Dimensi Flange Slip-on Kelas 150

| Ukuran ing Inci | Ukuran ing mm | Diameter njaba. | Flensa Tebal. | Hub OD | Dawane Flensa | Diameter RF. | Dhuwur RF | PCD | Soket Bor | Cacahing Baut | Ukuran Baut UNC | Dawane Baut Mesin | Dawane Stud RF | Ukuran Bolongan | Ukuran Stud ISO | Bobot ing kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Dimensi Flange Leher Las Kelas 150

| Ukuran ing Inci | Ukuran ing mm | Diameter njaba | Ketebalan Flensa | Hub OD | Leher Las OD | Dawane Leher Las | Bolongan | Diameter RF | Dhuwur RF | PCD | Lasan Rai |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Bor leher las dijupuk saka jadwal pipa | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Dimensi Flange Buta Kelas 150

| Ukuran | Ukuran | Njaba | Flens | RF | RF | PCD | Ora ana | Ukuran Baut | Baut Mesin | Stud RF | Ukuran Bolongan | ISO Stud | Bobot |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Standar & Kelas

| ASME B16.5: Flensa Pipa lan Fitting Flensa | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| EN 1092-1: Flensa lan Sambungane - Flensa Bunder kanggo Pipa, Katup, Fitting, lan Aksesoris, PN Ditunjuk - Bagian 1: Flensa Baja | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan

|

| DIN 2501: Flensa lan Sambungan Lapped | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| GOST 33259: Flensa kanggo Katup, Fitting, lan Pipa kanggo Tekanan nganti PN 250 | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| SABS 1123: Flensa kanggo Pipa, Katup, lan Fitting | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

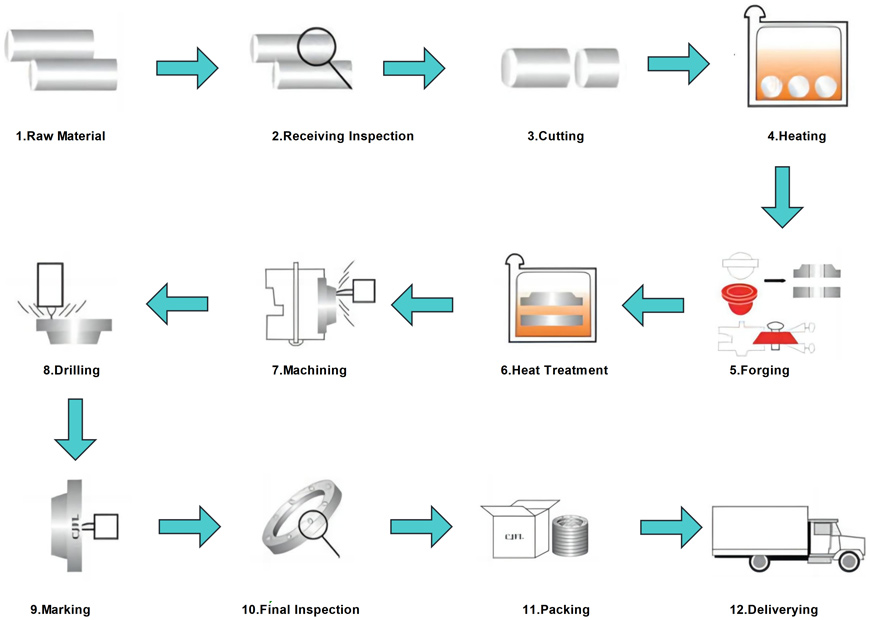

Proses Manufaktur

Kontrol Kualitas

Pamriksaan Bahan Baku, Analisis Kimia, Uji Mekanik, Inspeksi Visual, Pamriksaan Dimensi, Uji Lentur, Uji Perataan, Uji Impak, Uji DWT, Pamriksaan Non-Destruktif(UT, MT, PT, Sinar-X,), Uji Kekerasan, Uji Tekanan, Uji Kebocoran Kursi, Uji Metalografi, Uji Korosi, Uji Tahan Geni, Uji Semprotan Uyah, Uji Kinerja Aliran, Uji Torsi lan Dorongan, Inspeksi Pengecatan lan Pelapisan, Tinjauan Dokumentasi…..

Panggunaan & Aplikasi

Flensa minangka bagean industri penting sing digunakake kanggo nyambungake pipa, katup, peralatan, lan komponen pipa liyane. Flensa nduweni peran penting kanggo nyambungake, ndhukung, lan nutup sistem pipa. Flensa minangka komponen penting ing macem-macem aplikasi industri, kalebu:

● Sistem Perpipaan

● Katup

● Peralatan

● Koneksi

● Nyegel

● Manajemen Tekanan

Pengepakan & Pengiriman

Ing Womic Steel, kita ngerti pentinge kemasan sing aman lan pengiriman sing bisa dipercaya nalika ngirim pipa berkualitas tinggi menyang ngarep omah sampeyan. Iki ringkesan babagan prosedur kemasan lan pengiriman kanggo referensi sampeyan:

Kemasan:

Flensa pipa kita dikemas kanthi ati-ati kanggo mesthekake yen tekan sampeyan kanthi kondisi sing sampurna, siap kanggo kabutuhan industri utawa komersial sampeyan. Proses pengemasan kita kalebu langkah-langkah penting ing ngisor iki:

● Inspeksi Kualitas: Sadurunge dikemas, kabeh flensa ngalami inspeksi kualitas sing tliti kanggo ngonfirmasi yen wis memenuhi standar kinerja lan integritas sing ketat.

● Lapisan Pelindung: Gumantung saka jinis bahan lan aplikasi, flensa kita bisa uga nampa lapisan pelindung kanggo nyegah korosi lan kerusakan sajrone transportasi.

● Bundelan Aman: Flensa dibundel kanthi aman, njamin supaya tetep stabil lan dilindhungi sajrone proses pengiriman.

● Label lan Dokumentasi: Saben paket diwenehi label kanthi jelas nganggo informasi penting, kalebu spesifikasi produk, jumlah, lan pandhuan penanganan khusus. Dokumentasi sing relevan, kayata sertifikat kepatuhan, uga kalebu.

● Kemasan Khusus: Kita bisa nampung panjaluk kemasan khusus adhedhasar kabutuhan unik sampeyan, kanggo mesthekake yen flensa sampeyan disiapake persis kaya sing dibutuhake.

Pangiriman:

Kita kerja sama karo mitra pengiriman sing duwe reputasi apik kanggo njamin pengiriman sing bisa dipercaya lan tepat waktu menyang tujuan sing wis ditemtokake. Tim logistik kita ngoptimalake rute pengiriman kanggo nyuda wektu transit lan nyuda risiko penundaan. Kanggo pengiriman internasional, kita nangani kabeh dokumentasi bea cukai lan kepatuhan sing dibutuhake kanggo nggampangake bea cukai sing lancar. Kita nawakake pilihan pengiriman sing fleksibel, kalebu pengiriman sing dipercepat kanggo kabutuhan sing mendesak.