Katrangan Produk

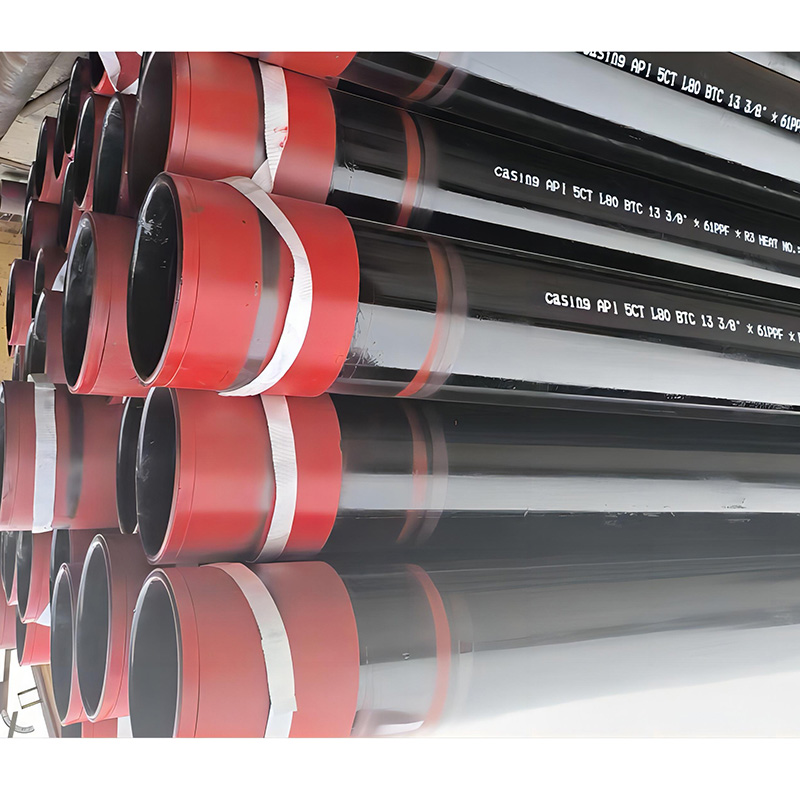

Casing lan pipa digunakake sacara wiyar kanggo pangembangan lenga lan gas. Casing lan pipa minangka komponen penting ing industri lenga lan gas sing digunakake kanggo ekstraksi lan transportasi hidrokarbon (lenga lan gas alam) saka reservoir lemah menyang permukaan. Casing lan pipa nduweni peran penting kanggo njamin keamanan, integritas, lan efisiensi operasi pengeboran lan produksi.

Pipa iku sawijining jinis pipa sing digunakake kanggo mindhah lenga mentah lan gas alam saka lapisan lenga utawa lapisan gas menyang lemah sawise pengeboran rampung. Pipa bisa ngidini tekanan sing diasilake sajrone proses ekstraksi. Pipa digawe kanthi cara sing padha karo casing, nanging proses sing diarani "upsetting" uga dibutuhake kanggo ngencerake pipa pipa.

Casing digunakake kanggo nglindhungi bolongan bor sing wis digali ing lemah kanggo nggoleki lenga. Digunakake padha karo pipa bor, pipa casing sumur lenga uga ngidini tekanan tegangan aksial, mula baja kekuatan tinggi sing berkualitas tinggi dibutuhake. Casing OCTG yaiku pipa diameter gedhe sing disemen menyang bolongan bor.

Spesifikasi

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Daftar Casing Baja ISO/API

| Labela | Ing njaba diameter D mm | Nominal linier massab, c Syarat & Ketentuan kg/m² | Tembok kekandelan t mm | Jenis pungkasan | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB (Publik) PLB (Publik) — | — — PLB (Publik) PLB (Publik) — | — — PLB (Publik) PLB (Publik) — | — — PLB (Publik) PLB (Publik) — | — — PLB (Publik) PLB (Publik) PLB (Publik) | — — — — PLB (Publik) |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB (Publik) PLB (Publik) PLB (Publik) — — | — — PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | — — PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | — — PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | — — PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | — — — PLBE PLB (Publik) PLB (Publik) PLB (Publik) |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB (Publik) PLB (Publik) PLB (Publik) | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB (Publik) PLB (Publik) — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB (Publik) PLB (Publik) PLB (Publik) PLB (Publik) — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Delengen cathetan ing pungkasan tabel. | ||||||||||||

| Labela | Ing njaba diameter D mm | Nominal linier massab, c Syarat & Ketentuan kg/m² | Tembok kekandelan t mm | Jenis pungkasan | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB (Publik) PLB (Publik) | PLBE PLBE PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | PLBE PLBE PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | PLBE PLBE PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) P P | PLBE PLBE PLBE PLB (Publik) PLB (Publik) PLB (Publik) | PLBE PLB (Publik) PLB (Publik) PLB (Publik) |

| 7-3/4 | 46.10 | 19.685 | 6.860 | 1.511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB (Publik) — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB (Publik) PLB (Publik) — — — — — — | — — PLBE PLBE PLBE PLBE PLB (Publik) — — — — | — — PLBE PLBE PLBE PLBE PLB (Publik) — — — — | — — PLBE PLBE PLBE PLBE PLB (Publik) P P P P | — — — PLBE PLBE PLBE PLB (Publik) — — — — | — — — — PLBE PLBE PLB (Publik) — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Delengen cathetan ing pungkasan tabel. | ||||||||||||

| Labela | Ing njaba diameter D mm | Nominal linier massab, c Syarat & Ketentuan kg/m² | Tembok kekandelan t mm | Jenis pungkasan | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1,Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47.308 | 13.021 | 1.105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Ujung polos, S = Benang bunder cendhak, L = Benang bunder dawa, B = Benang penopang, E = Garis ekstrem. | ||||||||||||

| ♦ Label kanggo informasi lan pitulungan nalika pesen. ♦ Massa linier nominal, sing diulir lan digandheng (kol. 2) dituduhake mung kanggo informasi. ♦ Kapadhetan baja kromium martensitik (jinis L80 9Cr lan 13Cr) beda karo baja karbon. Mula, massa sing dituduhake ora akurat kanggo baja kromium martensitik. Faktor koreksi massa 0,989 bisa digunakake. | ||||||||||||

| Label | Diameter njaba D mm | Linier ujung polos massa kg/m² | Kekandelan tembok t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Daftar Pipa Baja ISO/API

| Label | Ing njaba diameter D mm | Nominal linier massaa, b | Tembok kandel kebecikan t mm | Jenis pungkasaning rampesc | |||||||||||

| Non- nesu Syarat & Ketentuan kg/m² | Ekst. nesu Syarat & Ketentuan kg/m² | Integ. sendi kg/m² | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Syarat & Ketentuan | EU Syarat & Ketentuan | IJ | H40 | J55 | L80 | N80 Tipe 1,Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Ujung polos, N = Ulir lan sambungan sing ora kenceng, U = Ulir lan sambungan sing kenceng saka njaba, I = Sambungan integral. | |||||||||||||||

| ♦ Massa linier nominal, ulir, lan kopling (kol. 2, 3, 4) dituduhake mung kanggo informasi. ♦ Kapadhetan baja kromium martensitik (jinis L80 9Cr lan 13Cr) beda karo baja karbon. Mula, massa sing dituduhake ora akurat kanggo baja kromium martensitik. Faktor koreksi massa 0,989 bisa digunakake. ♦ Pipa non-upset kasedhiya karo kopling biasa utawa kopling bevel khusus. Pipa eksternal-upset kasedhiya karo kopling jarak biasa, bevel khusus, utawa khusus. | |||||||||||||||

Standar & Kelas

Casing lan pipa Kelas Standar:

API 5CT J55, K55, L80, N80, P110, C90, T95, H40

Ujung pipa lan selubung API 5CT:

(STC) Selubung ulir bunder cendhak

(LC) Selubung ulir bunder dawa

(BC) Selubung ulir penopang

(XC) Casing garis ekstrem

(NU) Pipa sing ora kenceng

(EU) Pipa upset njaba

(IJ) Pipa sambungan integral

Casing lan pipa kudu dikirim miturut sambungan ing ndhuwur karo standar API5CT / Standar API.

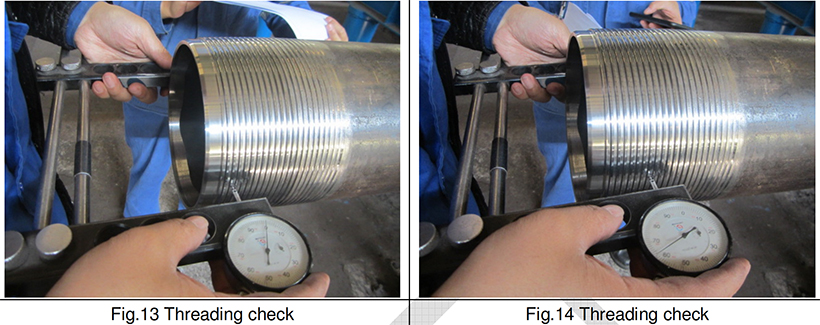

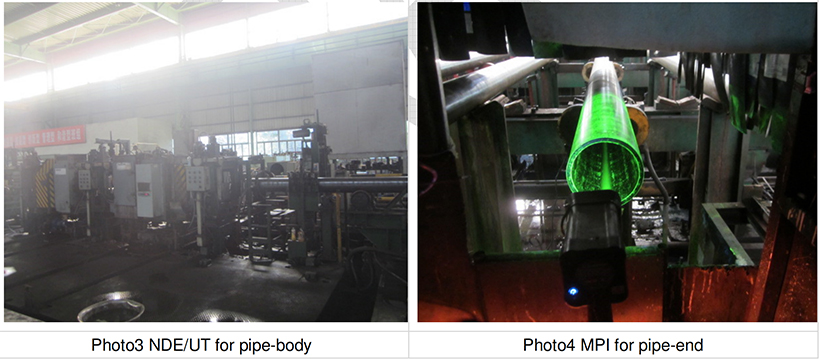

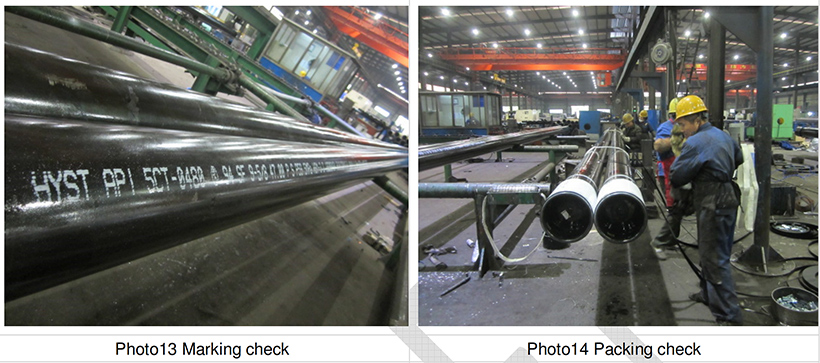

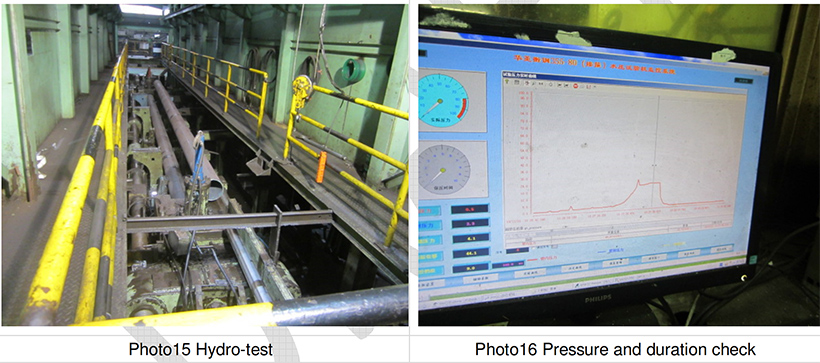

Kontrol Kualitas

Pamriksaan Bahan Baku, Analisis Kimia, Uji Mekanik, Inspeksi Visual, Uji Tegangan, Pamriksaan Dimensi, Uji Lentur, Uji Perataan, Uji Impak, Uji DWT, Uji NDT, Uji Hidrostatik, Uji Kekerasan…..

Nandhani, ngecet sadurunge pangiriman.

Pengepakan & Pengiriman

Cara pengemasan pipa baja kalebu ngresiki, nglompokake, mbungkus, nggabung, ngamanake, menehi label, menehi palet (yen perlu), ngemas wadhah, nyimpen, nyegel, ngangkut, lan mbongkar. Macem-macem jinis pipa lan perlengkapan baja kanthi cara pengemasan sing beda-beda. Proses lengkap iki njamin pipa baja dikirim lan tekan tujuan kanthi kondisi optimal, siap kanggo panggunaan sing dikarepake.

Panggunaan & Aplikasi

Pipa baja dadi tulang punggung teknik industri lan sipil modern, ndhukung macem-macem aplikasi sing nyumbang kanggo pangembangan masyarakat lan ekonomi ing saindenging jagad.

Pipa lan perlengkapan baja sing diprodhuksi Womic Steel digunakake sacara wiyar kanggo pipa minyak bumi, gas, bahan bakar & banyu, lepas pantai / darat, proyek konstruksi pelabuhan laut & bangunan, pengerukan, baja struktural, proyek konstruksi tiang pancang lan jembatan, uga tabung baja presisi kanggo produksi roller conveyor, lsp...