Pambuka:

API 5L iku spesifikasi standar sing ditetepake dening American Petroleum Institute (API) kanggo pipa baja tanpa sambungan lan dilas sing digunakake ing sistem transportasi ing industri minyak bumi lan gas alam. Womic Steel, produsen pipa API 5L sing unggul, nawakake macem-macem produk sing memenuhi macem-macem kelas lan spesifikasi. Artikel iki nyedhiyakake perbandingan rinci babagan komposisi kimia, sifat mekanik, lan standar pengujian kanggo macem-macem kelas API 5L, PSL1 lan PSL2 ing telung jinis pipa: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), lan SMLS (Seamless).

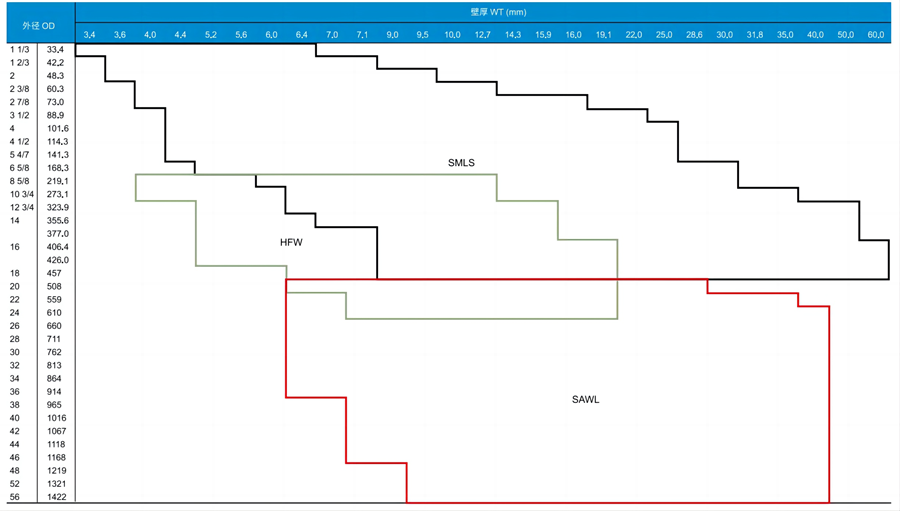

Kapabilitas lan Jangkauan Produksi:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Min mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Toleransi Diameter Luar

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| SPESIFIKASI API SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0,75%/-0,75% | ≤2.0% | ≤1,5% | ||||

| 168,3mm | +0,5%/-0,5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0,75%/-0,75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0,5%/-0,5% | ±2.0mm | ±1.6mm | ≤1,5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Cathetan: D iku diameter njaba nominal pipa.

Toleransi Kekandelan Tembok

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| SPESIFIKASI API ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12,5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst <25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

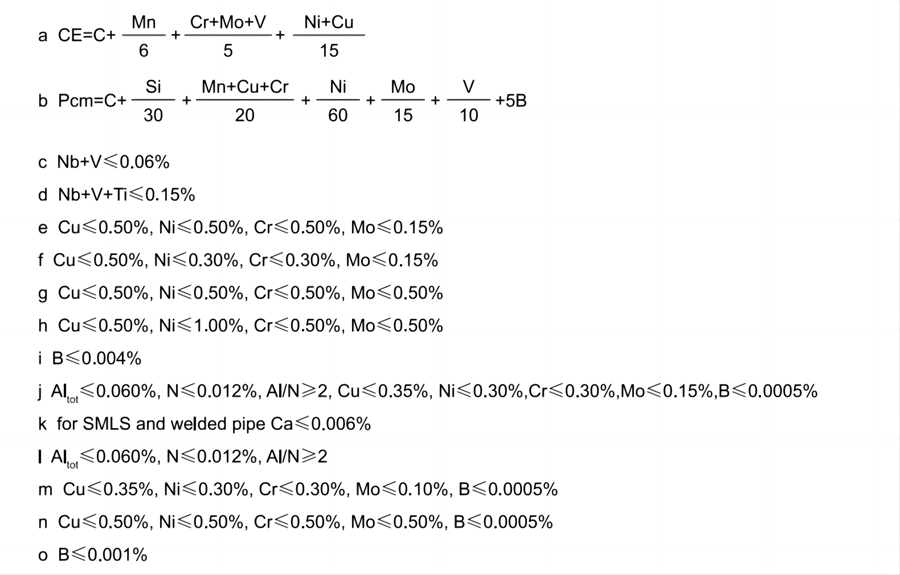

Analisis Kimia

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | |||||

| API SPESIFIKASI 5L | 无缝管 | PSL1 | L210 utawa A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 utawa B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 utawa X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 utawa X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 utawa X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 utawa X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 utawa X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 utawa X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 utawa X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N utawa BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N utawa X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N utawa X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N utawa X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N utawa X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N utawa X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Kaya sing wis disepakati | d,g,o | ||||

| L245Q utawa BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q utawa X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q utawa X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 utawa ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q utawa X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q utawa X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q utawa X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q utawa X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q utawa X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Kaya sing wis disepakati | h, aku | ||||

| 酸性服 | L245NS utawa BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS utawa X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS utawa X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS utawa X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS utawa BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS utawa X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS utawa X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS utawa X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS utawa X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS utawa X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS utawa X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS utawa X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | |||||

| AP|SPEKS 5L | 无缝管 | 海上服 | L245NO utawa BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,aku,m |

| L290NO utawa X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO utawa X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, aku, m | |||

| L360NO utawa X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, Aku | |||

| L245QO utawa BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO utawa X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO utawa X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO utawa X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO utawa X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO utawa X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO utawa X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 utawa X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO utawa X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Kaya sing wis disepakati | d,I,n | ||||

| 焊管 | PSL1 | L245 utawa B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 utawa X42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 utawa X46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 utawa X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 utawa X56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 utawa X60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 utawa X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 utawa X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M utawa BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M utawa X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M utawa X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M utawa X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M utawa X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M utawa X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M utawa X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M utawa X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M utawa X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | maksimal | |||||

| API SPESIFIKASI 5L | 焊管 | 酸性服 | L245MS utawa BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS utawa X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS utawa X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS utawa X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS utawa X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS utawa X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS utawa X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS utawa X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO utawa BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO utawa X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO utawa X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Aku, m | |||

| L360MO utawa X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO utawa X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO utawa X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO utawa X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO utawa X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO utawa X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPESIFIKASI 5L | PSL1 | L210 utawa A | Min | 210 | 335 | a |

| 335 |

| L245 utawa B | Min | 245 | 415 | a |

| 415 | ||

| L290 utawa X42 | Min | 290 | 415 | a |

| 415 | ||

| L320 utawa X46 | Min | 320 | 435 | a |

| 435 | ||

| L360 utawa X52 | Min | 360 | 460 | a |

| 460 | ||

| L390 utawa X56 | Min | 390 | 490 | a |

| 490 | ||

| L415 utawa X60 | Min | 415 | 520 | a |

| 520 | ||

| L450 utawa X65 | Min | 450 | 535 | a |

| 535 | ||

| L485 utawa X70 | Min | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N utawa BN | Min | 245 | 415 | a |

| 415 | |

| Maks. | 450 | 655 |

| 0.93 |

| |||

| L290N utawa X42N | Min | 290 | 415 | a |

| 415 | ||

| Maks. | 495 | 655 |

| 0.93 |

| |||

| L320N utawa X46N | Min | 320 | 435 | a |

| 435 | ||

| Maks. | 525 | 655 |

| 0.93 |

| |||

| L360N utawa X52N | Min | 360 | 460 | a |

| 460 | ||

| Maks. | 530 | 760 |

| 0.93 |

| |||

| L390N utawa X56N | Min | 390 | 490 | a |

| 490 | ||

| Maks. | 545 | 760 |

| 0.93 |

| |||

| L415N utawa X60N | Min | 415 | 520 | a |

| 520 | ||

| Maks. | 565 | 760 |

| 0.93 |

| |||

| L450Q utawa X65Q | Min | 450 | 535 | a |

| 535 | ||

| Maks. | 600 | 760 |

| 0.93 |

| |||

| L485Q utawa X70Q | Min | 485 | 570 | a |

| 570 | ||

| Maks. | 635 | 760 |

| 0.93 |

| |||

| L555Q utawa X80Q | Min | 555 | 625 | a |

| 625 | ||

| Maks. | 705 | 825 |

| 0.93 |

| |||

| L625M utawa X90M | Min | 625 | 695 | a |

| 695 | ||

| Maks. | 775 | 915 |

| 0.95 |

| |||

| L690M utawa X100M | Min | 690 | 760 | a |

| 760 | ||

| Maks. | 840 | 990 |

| 0.97 |

| |||

| L830M utawa X120M | Min | 830 | 915 | a |

| 915 | ||

| Maks. | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPESIFIKASI 5L | 酸性服 | L245NS utawa BNS | Min | 245 | 415 | a |

| 415 |

| Maks. | 450 | 655 |

| 0.93 |

| |||

| L290NS utawa X42NS | Min | 290 | 415 | a |

| 415 | ||

| Maks. | 495 | 655 |

| 0.93 |

| |||

| L320NS utawa X46NS | Min | 320 | 435 | a |

| 435 | ||

| Maks. | 525 | 655 |

| 0.93 |

| |||

| L360NS utawa X52NS | Min | 360 | 460 | a |

| 460 | ||

| Maks. | 530 | 760 |

| 0.93 |

| |||

| L390QS utawa X56QS | Min | 390 | 490 | a |

| 490 | ||

| Maks. | 545 | 760 |

| 0.93 |

| |||

| L415QS utawa X60QS | Min | 415 | 520 | a |

| 520 | ||

| Maks. | 565 | 760 |

| 0.93 |

| |||

| L450QS utawa X65QS | Min | 450 | 535 | a |

| 535 | ||

| Maks. | 600 | 760 |

| 0.93 |

| |||

| L485QS utawa X70QS | Min | 485 | 570 | a |

| 570 | ||

| Maks. | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO utawa BNO | Min | 245 | 415 | a | - | 415 | |

| Maks. | 450 | 655 |

| 0.93 |

| |||

| L290NO utawa X42NO | Min | 290 | 415 | a |

| 415 | ||

| Maks. | 495 | 655 |

| 0.93 |

| |||

| L320NO utawa X46NO | Min | 320 | 435 | a |

| 435 | ||

| Maks. | 520 | 655 |

| 0.93 |

| |||

| L360NO utawa X52NO | Min | 360 | 460 | a |

| 460 | ||

| Maks. | 525 | 760 |

| 0.93 |

| |||

| L390QO utawa X56QO | Min | 390 | 490 | a |

| 490 | ||

| Maks. | 540 | 760 |

| 0.93 |

| |||

| L415QO utawa X60QO | Min | 415 | 520 | a | - | 520 | ||

| Maks. | 565 | 760 |

| 0.93 |

| |||

| L450QO utawa X65QO | Min | 450 | 535 | a | - | 535 | ||

| Maks. | 570 | 760 |

| 0.93 |

| |||

| L485Q0 utawa X70Q0 | Min | 485 | 570 | a |

| 570 | ||

| Maks. | 605 | 760 |

| 0.93 |

| |||

| L555QO utawa X80QO | Min | 555 | 625 | a |

| 625 | ||

| Maks. | 675 | 825 |

| 0.93 |

Cathetan: a: Elongasi minimal nggunakake persamaan ing ngisor iki: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 utawa X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 utawa X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 utawa X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 utawa X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Cathetan: (1) Nilai ing tabel kudu cocog kanggo sampel standar ukuran lengkap.

(2) Nilai ing njero kurung iku nilai tunggal minimal, kurung njaba iku nilai rata-rata.

(3) Suhu Tes: 0°C.

Standar Pengujian:

Pipa API 5L sing diprodhuksi dening Womic Steel ngalami uji coba sing ketat kanggo mesthekake yen pipa kasebut memenuhi standar kualitas paling dhuwur. Standar uji coba kasebut kalebu:

Analisis Kimia:

Komposisi kimia baja dianalisis kanggo verifikasi manawa baja kasebut memenuhi syarat spesifikasi API 5L.

Analisis kimia ditindakake nggunakake spektrometer maca langsung kanggo nemtokake komposisi unsur baja kanthi akurat.

Tes Mekanik:

Sifat mekanik kaya ta kekuatan luluh, kekuatan tarik, lan elongasi diuji kanggo mesthekake yen wis memenuhi syarat sing ditemtokake.

Pengujian mekanik ditindakake nggunakake mesin uji tarik 60 ton kanggo ngukur kekuatan lan daktilitas baja.

Pengujian Hidrostatik:

Pengujian hidrostatik ditindakake kanggo mriksa integritas pipa lan mesthekake yen bisa tahan karo syarat tekanan sing dikarepake.

Pipa-pipa diisi banyu lan diwenehi tekanan, kanthi durasi uji lan tingkat tekanan sing ditemtokake dening standar API 5L.

Uji Non-Destruktif (NDT):

Cara NDT kaya ta uji ultrasonik (UT) lan uji partikel magnetik (MT) digunakake kanggo ndeteksi cacat utawa diskontinuitas ing pipa.

UT digunakake kanggo ngenali cacat internal, dene MT digunakake kanggo ndeteksi cacat permukaan.

Uji Dampak:

Uji impak ditindakake kanggo neliti kekokohan baja ing suhu sing kurang.

Uji impak Charpy umume digunakake kanggo ngukur energi impak sing diserep dening baja.

Tes Kekerasan:

Uji kekerasan baja ditindakake kanggo ngevaluasi kekerasan baja, sing bisa nuduhake kekuwatan lan kesesuaian kanggo aplikasi tartamtu.

Tes kekerasan Rockwell asring digunakake kanggo ngukur kekerasan baja.

Pemeriksaan Mikrostruktur:

Pamriksaan mikrostruktur ditindakake kanggo netepake struktur serat lan kualitas baja sakabèhé.

Mikroskop metalurgi digunakake kanggo mriksa mikrostruktur baja lan ngenali kelainan apa wae.

Kanthi netepi standar pengujian sing ketat iki, Womic Steel njamin yen pipa API 5L-ne memenuhi syarat kualitas paling dhuwur lan nyedhiyakake kinerja sing bisa dipercaya ing macem-macem aplikasi industri.

Proses Produksi:

1. Pipa Baja Seamless:

- Pilihan Bahan Baku: Bilet baja bunder kualitas dhuwur dipilih kanggo produksi pipa baja tanpa sambungan.

- Pemanasan lan Penusukan: Bilet-bilet kasebut dipanasake nganti suhu dhuwur banjur ditusuk kanggo nggawe cangkang sing kopong.

- Nggulung lan Ngukur Ukuran: Cangkang sing wis ditusuk banjur digulung lan diulur nganti tekan diameter lan kekandelan sing dikarepake.

- Perlakuan Panas: Pipa-pipa kasebut ngalami proses perlakuan panas kayata annealing utawa normalisasi kanggo ningkatake sifat mekanike.

- Rampungan: Pipa-pipa kasebut ngalami proses rampungan kayata pelurusan, pemotongan, lan inspeksi.

- Pengujian: Pipa-pipa kasebut ngalami macem-macem tes, kalebu uji hidrostatik, uji ultrasonik, lan uji arus eddy, kanggo njamin kualitase.

- Perawatan Permukaan: Pipa-pipa kasebut bisa dilapisi utawa diolah kanggo nyegah korosi lan nambah penampilane.

- Pengemasan lan Pengiriman: Pipa-pipa kasebut dikemas kanthi ati-ati lan dikirim menyang pelanggan.

2. Pipa Baja LSAW (Pengelasan Busur Terendam Longitudinal):

- Persiapan Pelat: Pelat baja berkualitas tinggi disiapake kanggo produksi pipa LSAW.

- Mbentuk: Pelat-pelat kasebut dibentuk dadi bentuk "U" nggunakake mesin sing wis dilenturake.

- Pengelasan: Pelat awujud "U" banjur dilas bebarengan nggunakake proses pengelasan busur terendam.

- Ekspansi: Sambungan sing dilas diekspansi nganti diameter sing dikarepake nggunakake mesin ekspansi internal utawa eksternal.

- Inspeksi: Pipa-pipa kasebut dipriksa kanggo cacat lan akurasi dimensi.

- Pengujian Ultrasonik: Pipa-pipa kasebut dites ultrasonik kanggo ndeteksi cacat internal.

- Beveling: Pucuk pipa miring kanggo ngelas.

- Pelapisan lan Penandaan: Pipa-pipa kasebut bisa dilapisi lan ditandhani miturut kabutuhan pelanggan.

- Pengemasan lan Pengiriman: Pipa-pipa kasebut dikemas lan dikirim menyang pelanggan.

3. Pipa Baja HFW (Pengelasan Frekuensi Tinggi):

- Persiapan Kumparan: Kumparan baja disiyapake kanggo produksi pipa HFW.

- Mbentuk lan Ngelas: Kumparan dibentuk dadi bentuk silinder banjur dilas nggunakake pengelasan frekuensi tinggi.

- Pemanasan Sambungan Las: Sambungan las dipanasake nganti suhu las nggunakake pemanasan induksi frekuensi dhuwur.

- Ukuran: Pipa sing dilas diukur miturut diameter lan kekandelan sing dibutuhake.

- Motong lan Miring: Pipa dipotong miturut dawa sing dikarepake lan pucuke miring kanggo dilas.

- Inspeksi: Pipa-pipa kasebut dipriksa kanggo cacat lan akurasi dimensi.

- Uji Hidrostatik: Pipa-pipa kasebut diuji kekuatan lan kebocorane nggunakake uji hidrostatik.

- Pelapisan lan Penandaan: Pipa-pipa kasebut dilapisi lan ditandhani miturut kabutuhan pelanggan.

- Pengemasan lan Pengiriman: Pipa-pipa kasebut dikemas lan dikirim menyang pelanggan.

Proses produksi sing rinci iki njamin kualitas lan keandalan pipa baja seamless, LSAW, lan HFW sing dhuwur sing diprodhuksi dening Womic Steel, sing nyukupi syarat ketat saka macem-macem industri.

Perawatan Permukaan:

Perawatan permukaan baja pipa iku penting banget kanggo ningkatake ketahanan korosi lan umur layanan. Womic Steel nggunakake macem-macem metode perawatan permukaan gumantung saka kabutuhan klien sing beda-beda, kalebu:

1. Galvanisasi celup panas: Pipa baja dicelupake ing seng cair kanggo mbentuk lapisan pelindung paduan seng-besi, sing nambah ketahanan korosi. Galvanisasi celup panas cocok kanggo pipa konvensional lan tekanan rendah.

2. Lapisan Anti-korosi: Lapisan anti-korosi sing umum kalebu lapisan epoksi, lapisan polietilen, lan lapisan poliuretan. Lapisan iki kanthi efektif nyegah oksidasi lan korosi ing permukaan pipa baja, saengga umur layanane luwih dawa.

3. Sandblasting: Blasting abrasif kecepatan tinggi digunakake kanggo ngresiki pipa baja, mbusak teyeng lan rereged saka permukaan, nyedhiyakake pondasi sing apik kanggo perawatan lapisan sabanjure.

4. Perawatan Pelapisan: Permukaan pipa baja bisa dilapisi cat anti korosi, cat aspal, lan lapisan liyane kanggo nambah ketahanan korosi, cocok kanggo pipa lemah lan pipa ing lingkungan laut.

Cara perawatan permukaan iki kanthi efektif nglindhungi baja pipa saka korosi lan kerusakan, njamin keandalan lan daya tahan ing macem-macem lingkungan sing atos.

Pengemasan lan Transportasi:

Womic Steel njamin kemasan sing aman lan transportasi pipa baja sing bisa dipercaya, nawakake pilihan fleksibel kanggo nyukupi macem-macem kabutuhan pelanggan:

1. Kargo Curah: Kanggo pesenan gedhe, baja pipa bisa dikirim kanthi akeh nggunakake pengangkut curah khusus. Baja kasebut dimuat langsung menyang palka kapal tanpa kemasan, cocok kanggo transportasi sing hemat biaya kanthi jumlah akeh.

2. LCL (Kurang saka Muatan Kontainer): Kanggo pesenan sing luwih cilik, baja pipa bisa dikirim minangka kargo LCL, ing ngendi pirang-pirang pesenan sing luwih cilik digabung dadi siji kontainer. Cara iki efektif biaya kanggo jumlah sing luwih cilik lan nawakake jadwal pangiriman sing luwih fleksibel.

3. FCL (Full Container Load): Pelanggan bisa milih pengiriman FCL, ing ngendi kontainer kebak dikhususake kanggo pesenan. Cara iki nyedhiyakake wektu transit sing luwih cepet lan nyuda risiko kerusakan sajrone penanganan.

4. Angkutan Udara: Kanggo pesenan sing penting banget, angkutan udara kasedhiya kanggo pangiriman sing cepet. Sanajan luwih larang tinimbang angkutan laut, angkutan udara nawakake transportasi sing cepet lan dipercaya kanggo kiriman sing sensitif wektu.

Womic Steel njamin kabeh kiriman dikemas kanthi aman kanggo nyegah kerusakan sajrone transportasi. Baja biasane dibungkus nganggo bahan pelindung lan diamanake ing wadhah utawa ing palet kanggo njamin stabilitas sajrone transit. Kajaba iku, perusahaan iki kerja sama karo mitra pengiriman sing duwe reputasi apik kanggo njamin pangiriman sing tepat wektu lan manajemen logistik sing efisien.

Skenario Aplikasi:

Pipa API 5L sing diprodhuksi dening Womic Steel akeh digunakake ing industri minyak bumi lan gas alam kanggo transportasi lenga, gas, lan cairan liyane. Pipa iki uga digunakake ing macem-macem industri liyane kayata pangolahan kimia, pembangkit listrik, lan konstruksi.

Dudutan:

Womic Steel minangka produsen pipa API 5L sing dipercaya, nawakake produk berkualitas tinggi sing nyukupi syarat ketat industri minyak bumi lan gas alam. Kanthi fokus ing kualitas, keandalan, lan kepuasan pelanggan, Womic Steel terus dadi pilihan sing disenengi para pelanggan ing saindenging jagad.

Wektu kiriman: 22 Maret 2024