Katrangan Produk

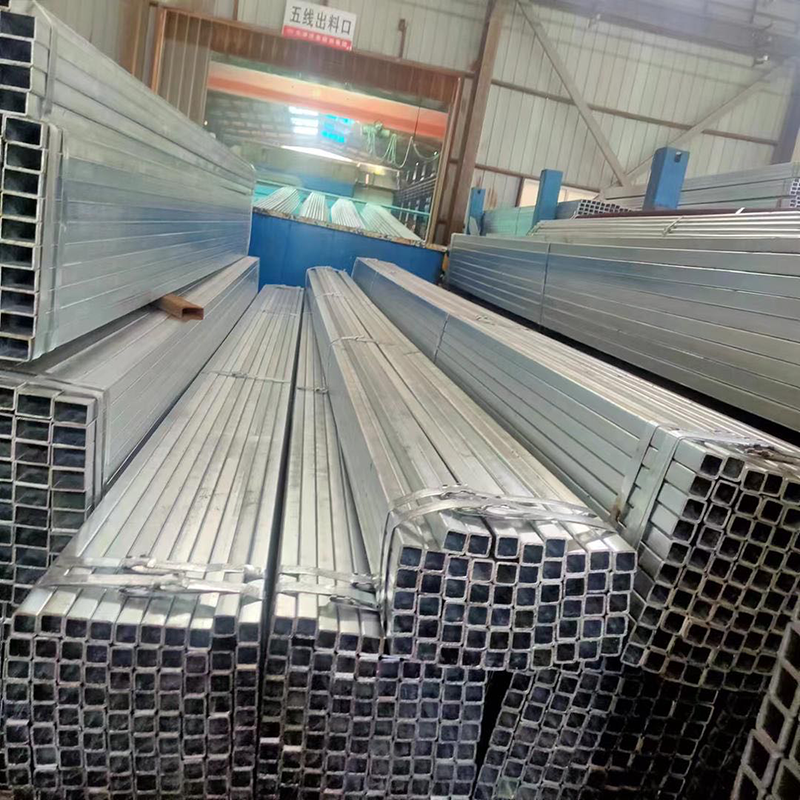

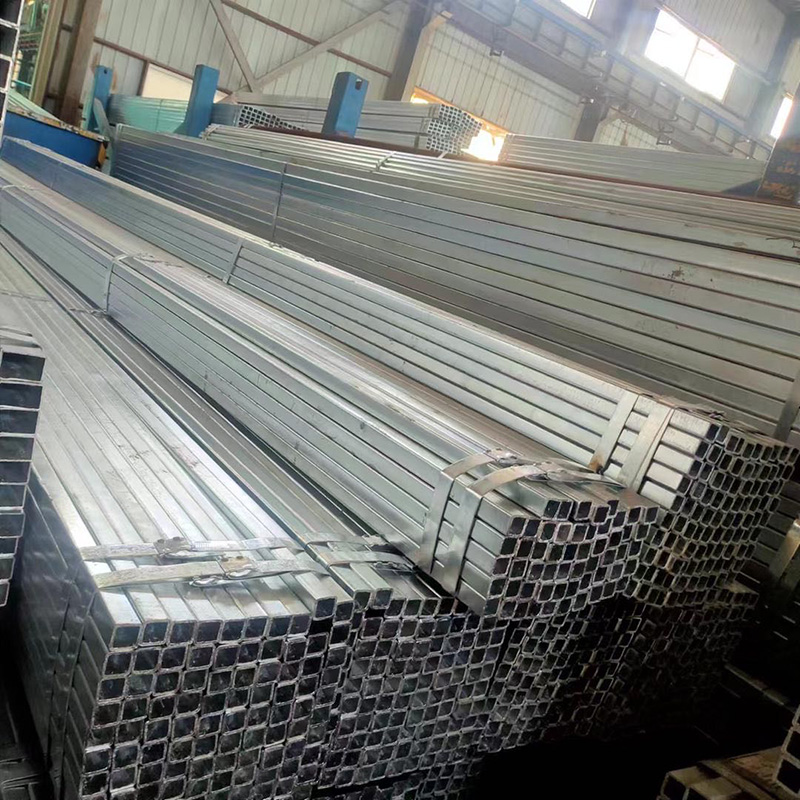

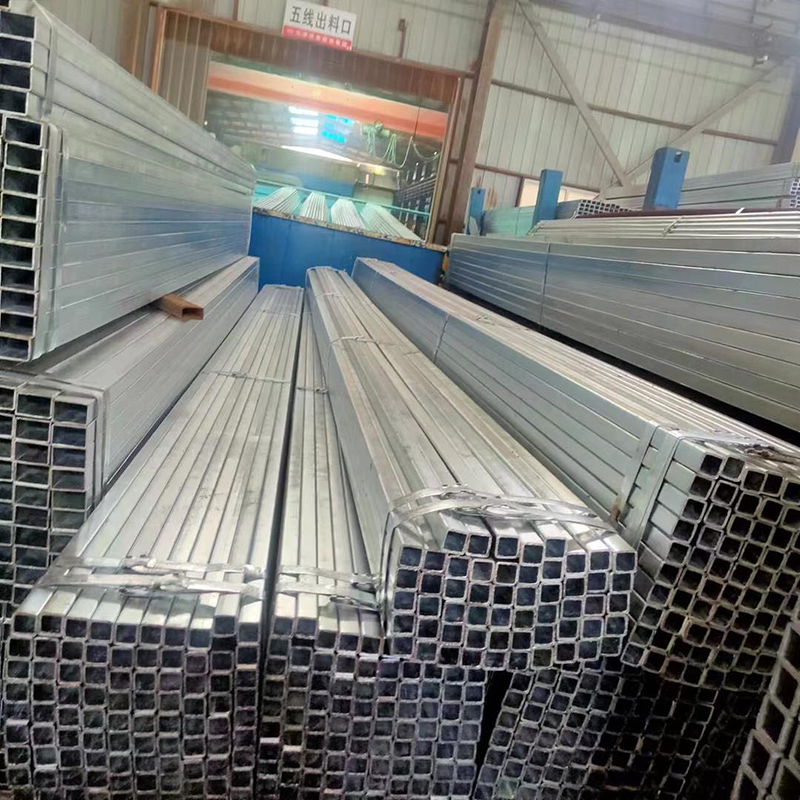

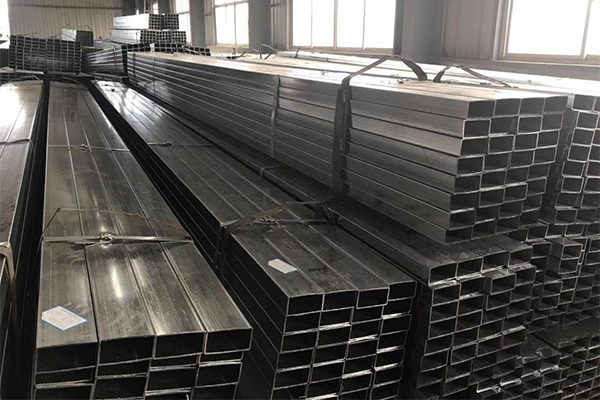

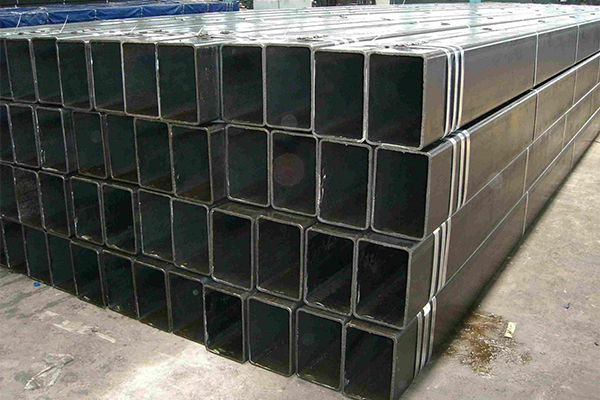

Pipa kothak & persegi panjang minangka pipa ekstrusi sing digunakake sacara wiyar kanggo kabeh jinis proyek fabrikasi ing ngendi entheng lan tahan korosi minangka perhatian utama. Pipa kothak nduweni pojok kothak ing njero lan njaba, tanpa sambungan las.

Pipa kothak & persegi panjang minangka bahan bangunan sing serbaguna, awet, lan hemat biaya sing digunakake ing konstruksi, industri, mebel, lan aplikasi dekoratif. Womic Steel nawakake macem-macem tabung baja kothak kanthi macem-macem ukuran lan kekandelan.

Bagian kothong persegi panjang/persegi dibentuk saka gulungan banjur dilas liwat serangkaian cetakan. Bagian kasebut dilas saka njero kanggo mbentuk wujude dhewe.

Proses potongan kopong (tabung persegi/persegi panjang):

● Bagean Kosong Kothak sing Dibentuk Adhem

● Bagean Kosong Persegi Panjang sing Dibentuk Adhem

● Bagian Kosong Kothak Finish Panas

● Bagian Berongga Persegi Panjang Berlapis Panas

Klasifikasi Proses Produksi Pipa Baja Persegi

Miturut proses produksi, pipa kothak dipérang dadi: pipa kothak tanpa sambungan sing digulung panas, pipa kothak tanpa sambungan sing ditarik adhem, pipa kothak sing diekstrusi tanpa dimensi, lan pipa kothak sing dilas.

Pipa kothak/persegi panjang sing dilas dipérang dadi:

(a) miturut proses pipa kothak sing dilas busur, pipa kothak sing dilas resistensi (frekuensi dhuwur, frekuensi endhek), pipa kothak sing dilas gas, pipa kothak sing dilas tungku.

(b) miturut las pipa kothak sing dilas lurus, pipa kothak sing dilas spiral.

Spesifikasi

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| BS 1387: Kelas A, Kelas B |

| ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Kelas C250, Kelas C350, Kelas C450 |

| SANS 657-3: 2015 |

| Ukuran produksi pipa/tabung baja persegi: Diameter njaba: 16*16mm ~ 1000*1000mm Kekandelan tembok: 0.4mm ~ 50mm | |

| Ukuran miturut MM (diameter) | Kekandelan |

| mm | mm |

| 16mm×16mm | 0.4mm ~ 1.5mm |

| 18mm×18mm | 0.4mm ~ 1.5mm |

| 20mm×20mm | 0.4mm ~ 3mm |

| 22mm×22mm | 0.4mm ~ 3mm |

| 25mm×25mm | 0.6mm ~ 3mm |

| 30mm×30mm | 0.6mm ~ 4mm |

| 32mm×32mm | 0.6mm ~ 4mm |

| 34mm×34mm | 1mm ~ 2mm |

| 35mm×35mm | 1mm ~ 4mm |

| 38mm×38mm | 1mm ~ 4mm |

| 40mm×40mm | 1mm ~ 4.5mm |

| 44mm×44mm | 1mm ~ 4.5mm |

| 45mm×45mm | 1mm ~ 5mm |

| 50mm × 50mm | 1mm ~ 5mm |

| 52mm×52mm | 1mm ~ 5mm |

| 60mm × 60mm | 1mm ~ 5mm |

| 70mm×70mm | 2mm ~ 6mm |

| 75mm×75mm | 2mm ~ 6mm |

| 76mm×76mm | 2mm ~ 6mm |

| 80mm×80mm | 2mm ~ 8mm |

| 85mm×85mm | 2mm ~ 8mm |

| 90mm×90mm | 2mm ~ 8mm |

| 95mm×95mm | 2mm ~ 8mm |

| 100mm × 100mm | 2mm ~ 8mm |

| 120mm × 120mm | 4mm nganti 8mm |

| 125mm × 125mm | 4mm nganti 8mm |

| 130mm×130mm | 4mm nganti 8mm |

| 140mm×140mm | 6mm nganti 10mm |

| 150mm × 150mm | 6mm nganti 10mm |

| 160mm×160mm | 6mm nganti 10mm |

| 180mm×180mm | 6mm nganti 12mm |

| 200mm×200mm | 6mm ~ 30mm |

| 220mm×220mm | 6mm ~ 30mm |

| 250mm×250mm | 6mm ~ 30mm |

| 270mm×270mm | 6mm ~ 30mm |

| 280mm×280mm | 6mm ~ 30mm |

| 300mm×300mm | 8mm ~ 30mm |

| 320mm×320mm | 8mm ~ 30mm |

| 350mm×350mm | 8mm ~ 30mm |

| 380mm×380mm | 8mm ~ 30mm |

| 400mm×400mm | 8mm ~ 30mm |

| 420mm×420mm | 10mm ~ 30mm |

| 450mm×450mm | 10mm ~ 30mm |

| 480mm×480mm | 10mm ~ 30mm |

| 500mm×500mm | 10mm ~ 30mm |

| 550mm×550mm | 10mm ~ 40mm |

| 600mm×600mm | 10mm ~ 40mm |

| 700mm×700mm | 10mm ~ 40mm |

| 800mm×800mm | 10mm ~ 50mm |

| 900mm×900mm | 10mm ~ 50mm |

| 1000mm × 1000mm | 10mm ~ 50mm |

| Ukuran produksi pipa/tabung baja persegi panjang: Diameter njaba: 40*20mm ~ 300*200mm Kekandelan tembok: 1.6mm ~ 16mm | ||||||

| UKURAN mm | Bobot kg/m | EST. LBS. PER FT. | UKURAN mm | Bobot kg/m | ||

| EST. LBS. PER FT. | ||||||

| 40 x 20 x 1.60 | 1.38 | 0.93 | 150 x 100 x 6.30 | 22.4 | 15.08 | |

| 40 x 20 x 2.60 | 2.1 | 1.41 | 150 x 100 x 8.00 | 27.7 | 18.64 | |

| 50x30x1.60 | 1.88 | 1.27 | 150 x 100 x 10.00 | 35.714 | 24.04 | |

| 50x30x2.60 | 2.92 | 1.97 | 160 x 80 x 3.20 | 11.5 | 7.74 | |

| 50x30x2.90 | 3.32 | 2.23 | 160 x 80 x 4.00 | 14.3 | 9.62 | |

| 50x30x3.20 | 3.49 | 2.35 | 160 x 80 x 5.00 | 17.4 | 11.71 | |

| 50x30x4.00 | 4.41 | 2.97 | 160 x 80 x 6.30 | 21.4 | 14.4 | |

| 60x40x2.60 | 3.73 | 2.51 | 160 x 80 x 8.00 | 26.4 | 17.77 | |

| 60 x 40 x 2.90 | 4.23 | 2.85 | 160 x 80 x 10.00 | 32.545 | 21.87 | |

| 60x40x3.20 | 4.5 | 3.03 | 160 x 90 x 4.50 | 16.6 | 11.17 | |

| 60 x 40 x 4.00 | 5.67 | 3.82 | 160 x 90 x 5.60 | 20.4 | 13.73 | |

| 70 x 40 x 2.90 | 4.69 | 3.16 | 160 x 90 x 7.10 | 25.3 | 17.03 | |

| 70 x 40 x 4.00 | 6.3 | 4.24 | 160 x 90 x 8.80 | 30.5 | 20.53 | |

| 80 x 40 x 2.60 | 4.55 | 3.06 | 160 x 90 x 10.00 | 34.1 | 22.95 | |

| 80 x 40 x 2.90 | 5.14 | 3.46 | 180 x 100 x 4.00 | 16.8 | 11.31 | |

| 80 x 40 x 3.20 | 5.5 | 3.7 | 180 x 100 x 5.00 | 20.5 | 13.8 | |

| 80 x 40 x 4.00 | 6.93 | 4.66 | 180 x 100 x 5.60 | 23 | 15.48 | |

| 80 x 40 x 5.00 | 8.47 | 5.7 | 180 x 100 x 6.30 | 25.4 | 17.09 | |

| 80 x 40 x 6.30 | 10.4 | 7 | 180 x 100 x 7.10 | 28.6 | 19.25 | |

| 90 x 50 x 2.60 | 5.37 | 3.61 | 180 x 100 x 8.80 | 34.7 | 23.35 | |

| 90x50x3.20 | 6.64 | 4.47 | 180 x 100 x 10.00 | 38.8 | 26.11 | |

| 90 x 50 x 4.00 | 8.18 | 5.51 | 180 x 100 x 12.50 | 46.9 | 31.56 | |

| 90 x 50 x 5.00 | 10 | 6.73 | 200 x 100 x 4.00 | 18 | 12.11 | |

| 90 x 50 x 6.30 | 12.3 | 8.28 | 200 x 100 x 5.00 | 22.1 | 14.2 | |

| 90 x 50 x 7.10 | 13.7 | 9.22 | 200 x 100 x 6.30 | 27.4 | 18.44 | |

| 100x50x3.60 | 7.98 | 5.37 | 200x100x8.00 | 34 | 22.88 | |

| 100x50x4.50 | 9.83 | 6.62 | 200x100x10.00 | 40.6 | 27.32 | |

| 100x50x5.60 | 12 | 8.08 | 200 x 120 x 4.00 | 19.3 | 12.99 | |

| 100x50x7.10 | 14.8 | 9.96 | 200 x 120 x 5.00 | 23.7 | 15.95 | |

| 100x50x8.00 | 16.4 | 11.04 | 200 x 120 x 6.30 | 29.6 | 19.92 | |

| 100x60x3.20 | 7.51 | 5.05 | 200 x 120 x 8.00 | 36.5 | 24.56 | |

| 100x60x3.60 | 8.55 | 5.75 | 200 x 120 x 8.80 | 36.9 | 24.83 | |

| 100x60x4.50 | 10.5 | 7.07 | 200 x 120 x 10.00 | 45.1 | 31.62 | |

| 100x60x5.60 | 12.9 | 8.68 | 200 x 120 x 12.50 | 54.7 | 38.87 | |

| 100x60x6.30 | 13.5 | 9.09 | 200 x 120 x 14.20 | 60.9 | 43.64 | |

| 100x60x7.10 | 15.9 | 10.7 | 220 x 80 x 6.00 | 26.816 | 18.02 | |

| 100x60x8.80 | 19.2 | 12.92 | 220 x 120 x 6.30 | 31.6 | 21.27 | |

| 100x80x6.3 | 16.37 | 11.02 | 220 x 120 x 8.00 | 39.4 | 26.52 | |

| 110 x 60 x 3.60 | 9.05 | 6.09 | 220 x 120 x 10.00 | 46.2 | 31.09 | |

| 110 x 60 x 4.50 | 11.1 | 7.47 | 220 x 120 x 12.50 | 58.7 | 39.51 | |

| 110 x 60 x 5.60 | 13.6 | 9.15 | 220 x 120 x 14.20 | 65.4 | 44.01 | |

| 110 x 60 x 7.10 | 16.8 | 11.31 | 250 x 150 x 5.00 | 29.9 | 20.12 | |

| 110 x 60 x 8.80 | 20.1 | 13.53 | 250 x 150 x 6.30 | 37.3 | 25.1 | |

| 110 x 70 x 3.20 | 8.51 | 5.73 | 250 x 150 x 8.00 | 46.5 | 31.29 | |

| 110 x 70 x 4.00 | 10.8 | 7.27 | 250 x 150 x 10.00 | 56.3 | 37.89 | |

| 110 x 70 x 5.00 | 12.7 | 8.55 | 250 x 150 x 12.50 | 68.3 | 45.97 | |

| 110 x 70 x 6.30 | 15.5 | 10.43 | 260 x 140 x 6.30 | 37.5 | 25.23 | |

| 120 x 60 x 3.20 | 8.51 | 5.73 | 260 x 140 x 8.00 | 46.9 | 31.56 | |

| 120 x 60 x 4.00 | 10.6 | 7.13 | 260 x 140 x 10.00 | 57.6 | 38.76 | |

| 120 x 60 x 5.00 | 13 | 8.75 | 260 x 140 x 12.50 | 70.4 | 47.38 | |

| 120 x 60 x 6.30 | 16.1 | 10.84 | 260 x 140 x 14.20 | 78.8 | 53.03 | |

| 120 x 60 x 7.10 | 17.9 | 12.05 | 260 x 180 x 6.30 | 41.5 | 27.93 | |

| 120 x 60 x 8.80 | 21.5 | 14.47 | 260 x 180 x 8.00 | 52 | 35 | |

| 120 x 80 x 3.20 | 12.1 | 8.14 | 260 x 180 x 10.00 | 63.9 | 43 | |

| 120 x 80 x 6.30 | 17.5 | 11.78 | 260 x 180 x 12.50 | 78.3 | 52.7 | |

| 140 x 70 x 4.00 | 12.5 | 8.41 | 260 x 180 x 14.20 | 87.7 | 59.02 | |

| 140 x 70 x 5.00 | 15.4 | 10.36 | 300 x 100 x 5.00 | 30.268 | 20.34 | |

| 140 x 70 x 6.30 | 19 | 12.79 | 300 x 100 x 8.00 | 47.679 | 32.04 | |

| 140 x 70 x 7.10 | 21.2 | 14.27 | 300 x 100 x 10.00 | 58.979 | 39.63 | |

| 140 x 70 x 8.80 | 25.6 | 17.23 | 300 x 200 x 5.00 | 37.8 | 25.44 | |

| 140 x 80 x 3.20 | 10.5 | 7.07 | 300 x 200 x 6.30 | 47.1 | 31.7 | |

| 140 x 80 x 4.00 | 13.1 | 8.82 | 300 x 200 x 8.00 | 59.1 | 39.77 | |

| 140 x 80 x 5.00 | 16.2 | 10.9 | 300 x 200 x 10.00 | 72 | 48.46 | |

| 140 x 80 x 6.30 | 20 | 13.46 | 300 x 200 x 12.00 | 88 | 59.22 | |

| 140 x 80 x 8.00 | 24.8 | 16.69 | ||||

| 140 x 80 x 10.00 | 30.2 | 20.32 | ||||

| 150 x 100 x 3.20 | 12 | 8.08 | ||||

| 150 x 100 x 4.00 | 14.9 | 10.03 | ||||

Standar & Kelas

ASTM A500 Grade B, ASTM A513 (1020-1026), ASTM A36 (A36), EN 10210:S235, S355, S235JRH, S355J2H, S355NH, EN 10219:S235, S355, S355, SH2 S275J2H, S355J0H, S355J2H.

| Komposisi kimia sakapipa persegi a & persegi panjangmateri | |||||

| Kelas | unsur | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0,05%-0,23% | 0,3%-0,6% | 0,04% | 0,04% |

| EN10027/1 | C% maksimal (WT Normal (mm) | Si% maksimal | Mn% maksimal | P% maksimal | S% maksimal | N% maksimal | |

| lan IC 10 | ≤ 40 | ||||||

| S235JRH | 0.17 | 0.2 | - | 1.4 | 0.045 | 0.045 | 0.009 |

| S275JOH | 0.2 | 0.22 | - | 1.5 | 0.04 | 0.04 | 0.009 |

| S275J2H | 0.2 | 0.22 | - | 1.5 | 0.035 | 0.035 | - |

| S355JOH | 0.22 | 0.22 | 0.55 | 1.6 | 0.04 | 0.04 | 0.009 |

| S355J2H | 0.22 | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | - |

| Sifat mekanik bahan | |||

| Kelas | Kekuatan Asil | Kekuwatan Tarik | Pemanjangan |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| Norma | Kekuatan Asil | Kekuwatan Tarik | Elogasi minimal | Properti minimal persen | ||||||||

| Akun kanggo EN10027/1 lan IC 10 | Akun kanggo EN10027/2 | WTmm Normal | WTmm Normal | Dawane. | Salib | Suhu uji coba°C | Nilai dampak minimal rata-rata | |||||

| ≤16 | >6 | >40 | <3 | ≤3≤65 | WTmm Normal | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

| Spesifikasi sing padha | ||||

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | – | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43°C | Fe 430 C |

| S275J2H | E 28-4 | Jalan 44.3 Lor | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50°C | Fe 510 C |

| S355J2H | E 36-4 | Jalan 52.3 Lor | 50 D | Fe 510 D |

| S275NH | – | St E 285 Lor | – | – |

| S275NLH | – | TSt E 285 Lor | 43 EE | – |

| S355NH | E 355 R | St E 355 Lor | – | – |

| S355NLH | – | TSt E 355 Lor | 50 EE | – |

| S460NH | E 460 R | St E 460 Lor | – | – |

| S460NLH | – | TSt E 460 Lor | 55 EE | – |

Kontrol Kualitas

Pamriksaan Bahan Baku, Analisis Kimia, Uji Mekanik, Inspeksi Visual, Uji Tegangan, Pamriksaan Dimensi, Uji Lentur, Uji Perataan, Uji Impak, Uji DWT, Uji NDT, Uji Hidrostatik, Uji Kekerasan…..

Nandhani, ngecet sadurunge pangiriman.

Pengepakan & Pengiriman

Cara pengemasan pipa baja kalebu ngresiki, nglompokake, mbungkus, nggabung, ngamanake, menehi label, menehi palet (yen perlu), ngemas wadhah, nyimpen, nyegel, ngangkut, lan mbongkar. Macem-macem jinis pipa lan perlengkapan baja kanthi cara pengemasan sing beda-beda. Proses lengkap iki njamin pipa baja dikirim lan tekan tujuan kanthi kondisi optimal, siap kanggo panggunaan sing dikarepake.

Panggunaan & Aplikasi

Pipa baja dadi tulang punggung teknik industri lan sipil modern, ndhukung macem-macem aplikasi sing nyumbang kanggo pangembangan masyarakat lan ekonomi ing saindenging jagad.

Pipa lan perlengkapan baja sing diprodhuksi Womic Steel digunakake sacara wiyar kanggo pipa minyak bumi, gas, bahan bakar & banyu, lepas pantai / darat, proyek konstruksi pelabuhan laut & bangunan, pengerukan, baja struktural, proyek konstruksi tiang pancang lan jembatan, uga tabung baja presisi kanggo produksi roller conveyor, lsp...